Test Before You Buy™

The Stedman Testing and Toll Processing Facility is the place to test your material in our full size equipment. If it can be crushed, ground, pulverized or mixed, chances are we’ve done it. We have more than 10,000 test reports to help get you to the best solution quickly. To learn more about what to expect from testing, read our article that ran in POWDER BULK ENGINEERING magazine.

Avoid Unplanned Downtime

It has happened to all of us; we have a great tool, possibly even our favorite, and when it finally needs a replacement part we are stuck hunting the internet and watching online auctions because the manufacturer discontinued the model. It’s frustrating that we are forced to buy the newest and sometimes less effective items just to get support from the manufacturer. At Stedman we support all of our equipment no matter the model or production date. From factory original replacements to wear items, we provide you the parts you need when you need them.

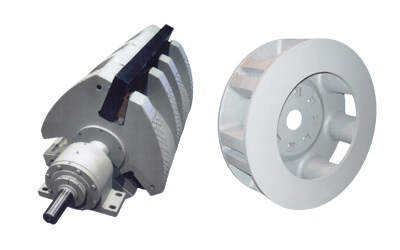

For after-sales support, Stedman has a complete inventory of impact crusher parts and spares including breaker bars, wear liners, bearings, electrical components and shafts. Cage mill parts including sleeves, bands and disks, are stocked for quick cage assembly.

After the sale is when you’ll truly appreciate Stedman Machine Company. All of our people are focused on industrial size reduction. You can be assured of dealing with experienced engineers, parts and service partners.

- The highest quality wear parts at the best prices

- Factory reconditioning of complete units - backed with a new crusher warranty

- Cage, rotor, shaft and apron assembly rebuilds

- Tubular rotor retrofits – Stedman V-Slam™ and select comparable brand VSI

- Shim Kit – hydraulic impactor apron adjustment

- 2nd Generation HSI heater package – cut maintenance downtime by over 50%

- Crush-Plus™/Max-Yield™ HSI Apron Adjustment &

- Grinding Path Systems

- Jack Screw wedge for quick breaker bar changes

- Hydraulic Cage Mill Housing Retractor Conversion

- Heaters & Air Canons for wet and sticky materials

Additional Information

Delivering equipment and service you deserve

For nearly two centuries, Stedman Machine Company has produced quality, reliable and durable size reduction and industrial crushing equipment. Stedman has expert field service and installation technicians ready to assist with all maintenance and equipment commissioning needs.

- Unsurpassed industry experience – operating since 1834

- State-of-the-art equipment testing facilities

- Dedicated, professional staff

- Parts and service available 24 hours a day

Stedman Machine is a leading cement crusher manufacturer with the capability to provide customer service across the globe. Our experienced team will work with you to create the best impact crusher system to make your processes the most efficient. Call us for more information!

Contact Us

Our 24 hour parts and service department along with our inventory of wear parts allow us to provide the fastest response time for parts and service.