How to Choose The Right Aggregate Crushing Equipment

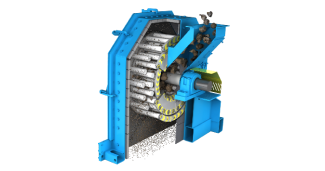

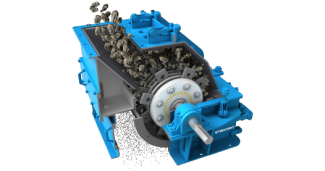

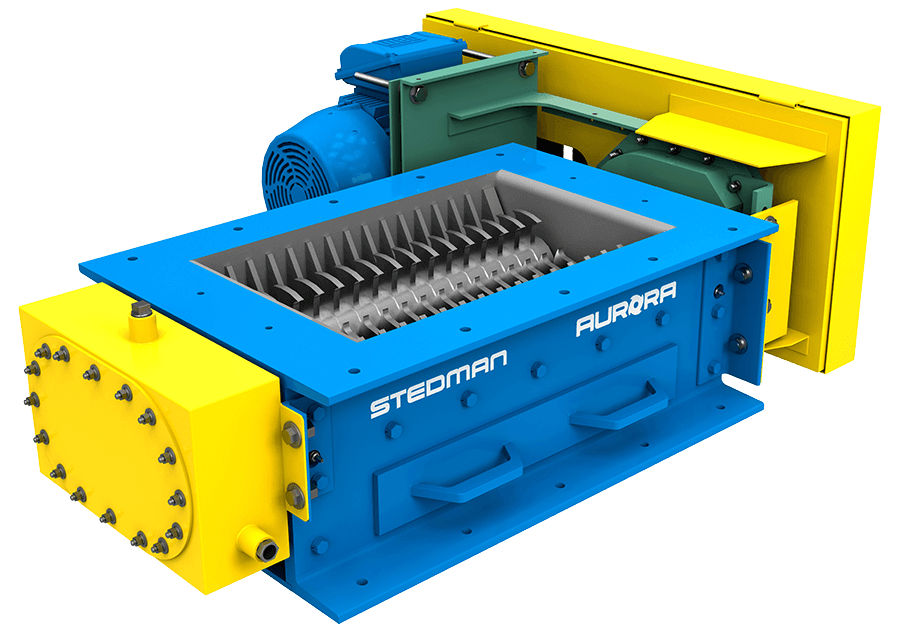

Primary crushers are first in a typical size reduction operation. Primaries like our Mega-Slam™ horizontal shaft impactor are commonly used in the aggregates industry to handle large feed sizes. The Grand-Slam™ HSI is well suited as secondary crusher for aggregate production for a wide range of materials including limestone, frac sand, gravel, stone, and more. Tertiary crushers are commonly used in the aggregates industry for final particle shaping to increase cubicity, and to produce a product size beyond what is capable from a primary or secondary. This stage of crushing is typically accomplished using a vertical shaft impactor or coarse, medium-fine, or fine grinding cage mill.

Limestone, sand, and gravel are used for building and public works projects. These materials are key ingredients in cement and asphalt for the construction of roads, buildings, and bridges.

Specialty uses of limestone include the manufacturing of pharmaceuticals, toothpaste, paint, paper, caulking, and glass. Flooring materials, carpets, and plastics all contain finely ground recycled limestone. Common antacids are virtually 100% finely ground limestone. Farmers can reuse limestone to neutralize acidity in their soils, saving money by reducing fertilizer use while improving crop yields.

Our field-proven rock and aggregate crushing equipment will give you years of dependable and profitable service. Innovative features make Stedman machines superior in performance.

Rock & Aggregate Crushing Equipment

View All Size Reduction Equipment

Aggregate & Rock Crusher Applications

- Limestone

- Sand & Gravel

- MSHA Rock Dust

- Gypsum

- Frac Sand

- Roof Shingles

- Sandstone

- Lightweight Aggregates

- Shale

- Chicken Grit

- Ice Grit

- Animal Feed Supplements

- Shells

Systems Design-Build

We provide dry material systems engineering and expertise in a variety of areas including crushing, screening, structures, conveyors, chutes, hoppers, dust collection, and storage. From small equipment retrofits to extensive turnkey facilities, our engineers make it happen. Successful projects always start with our client and us working together to define the problem. We follow a process that answers: What is the desired outcome of the project? At Stedman, we follow a simple method, ensuring that we provide customers with the highest value solution to their project.

Test Before You Buy™

The Stedman Testing and Toll Processing Facility is the place to test your material in our full size equipment. If it can be crushed, ground, pulverized or mixed, chances are we’ve done it. We have more than 10,000 test reports to help get you to the best solution quickly. To learn more about what to expect from testing, read our article that ran in POWDER BULK ENGINEERING magazine.

Aggregate Crushing Equipment Case Studies

Cage Mill Meets Most Aglime Specifications in One Pass

The 4-Row Cage Mill allows Aglime producers to meet most state Aglime specifications in an open circuit. It will economically produce Aglime to any specification for both large and small producers. The 4-Row Cage Mill feed does not have to be dry. Clogging, jamming and plugging are eliminated. Available with capacities as low as 5 TPH up to 100 TPH, the 4-Row Cage Mill produces consistent product quality.

Limestone Quarry Increases Production Capacity to 1.5 tons Yearly

Stedman Machine and Innovative Processing Solutions, an affiliate of Stedman, worked with Duff Quarry Inc. to incorporate two large industrial crushers to handle the size of limestone crushed annually. Their previous machines required a great amount of maintenance, but with Stedman machines, Duff Quarry Inc. spends less time fixing and more time crushing. With the installed plant and crushers, the quarry can produce up to 1.5 million tons of limestone a year running at full capacity.

Aggregates Industry Association Memberships

Stedman Machine Company is involved in professional organizations to better understand the knowledge and skills needed to serve our customers in the Aggregates Industry. These memberships give us better insight into the standards of the industry, updates to new and more efficient technologies and to the wants and needs of our customers. With the information obtained from our memberships, we can safely maintain the highest level of performance. Aggregate Industry associations include:

- IAAP (Illinois Association of Aggregate Producers)

- IMAA (Indiana Mineral Aggregates Association)

- KCSA (Kentucky Crushed Stone Association)

- NSSGA (National Stone, Sand & Gravel Association)

- OAIMA (Ohio Aggregates & Industrial Minerals Association)

- PACA (Pennsylvania Aggregates and Concrete Association)

Contact Us

Our 24 hour parts and service department along with our inventory of wear parts allow us to provide the fastest response time for parts and service.