Feeder System for Conveyors

Every material processing system has to have a starting point. Accurate, consistent feed rates are critical to ensure repeatable results in size reduction and separation systems. Overfeeding overloads conveyors and processing equipment, resulting in costly maintenance and downtime. Underfeeding robs production and increases costs.

Whether feeding small batches from bulk bags or high capacity from dump trucks, we help you select the appropriate feeder systems for conveyors to ensure your process begins well.

Typical feeding equipment includes:

- Apron feeders

- Belt feeders

- Vibratory pan feeders

- Vibratory grizzly feeders

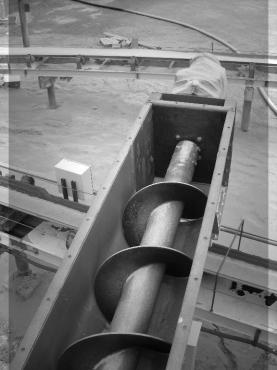

- Screw feeders

Bulk Material Handling Systems

Every processing system requires some form of material handling equipment. We select equipment that meets the needs of your project. Whether that means custom designing and fabricating a belt conveyor or working with other equipment manufacturers, we keep your material moving.

Improper design can cause a multitude of problems; spillage, fugitive dust, blocked chutes, uneven feed and accelerated wear on process equipment. We have the experience to design your dry bulk material handling system to eliminate these problems.

At Stedman Machine Company, we consider material characteristics, such as bulk density and material flow rates, as well as environmental factors when selecting and designing dry bulk material handling equipment. Thorough consideration is given to ensure the correct material handling solution for your unique project needs.

Typical dry bulk material handling equipment includes:

- Belt conveyors

- Stackers

- Bucket Conveyors

- Drag Conveyors

- Apron conveyors

- Screw conveyors

- Pneumatic conveying systems

Dry Bulk Storage Solutions

Stockpiling and storing raw, in-process and finished dry solid materials requires storage strategies.

After mining or production, dry solid material storage capacity must be matched to the entire system design. Well-designed dry bulk storage solutions allow for a continuously running system and protect the material from start to finish.

Stedman Machine Company will analyze your project storage tank needs and recommend a best-in-class solution.

Material Storage solutions include:

- Hoppers

- Surge bins

- Silos

- Bunkers

- Weathering sheds

- Reclaimers

- Stockpiles

Test Before You Buy™

The Stedman Testing and Toll Processing Facility is the place to test your material in our full size equipment. If it can be crushed, ground, pulverized or mixed, chances are we’ve done it. We have more than 10,000 test reports to help get you to the best solution quickly. To learn more about what to expect from testing, read our article that ran in POWDER BULK ENGINEERING magazine.

Additional Information

Delivering equipment and service you deserve

For nearly two centuries, Stedman Machine Company has produced quality, reliable and durable size reduction and industrial crushing equipment. Stedman has expert field service and installation technicians ready to assist with all maintenance and equipment commissioning needs.

- Unsurpassed industry experience – operating since 1834

- State-of-the-art equipment testing facilities

- Dedicated, professional staff

- Parts and service available 24 hours a day

Stedman Machine is a leading cement crusher manufacturer with the capability to provide customer service across the globe. Our experienced team will work with you to create the best impact crusher system to make your processes the most efficient. Call us for more information!

Contact Us

Our 24 hour parts and service department along with our inventory of wear parts allow us to provide the fastest response time for parts and service.