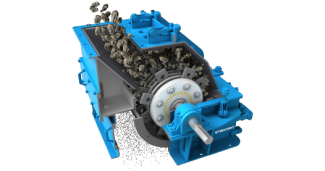

What is a Full Circle Hammer Mill?

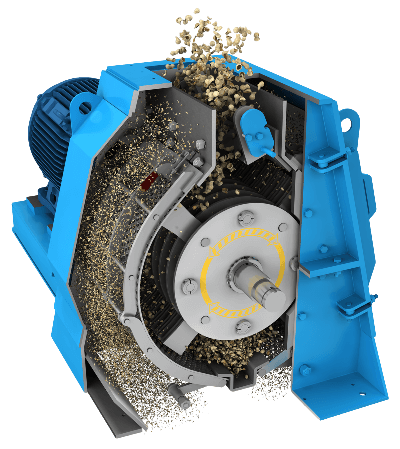

The Stedman Full Circle Hammer Mill is a fully reversible air-swept mill that targets a finer end product while increasing production capacity. It is perfect for a wide variety of industries where materials must be ground into a smaller particle size than a standard hammer mill. Our standard hammer mill uses a rain of hammer blows to shatter, crush and disintegrate materials, usually rocks and minerals, upon impact. The size of the finished product depends on the openings in screens or grates; the number, size, and type of hammers; the grinding plate setting; and the rotor speed.

Our full-circle hammer mill incorporates a turbulence channel at the bottom of the rotor which interrupts the material flow before returning it to the path of the hammers. This unique design delivers a finished product with much smaller – usually medium to fine – particle size.

Stedman’s full-circle hammer mill is perfect for a wide variety of industries where materials must be ground into a smaller particle size than a standard hammer mill.

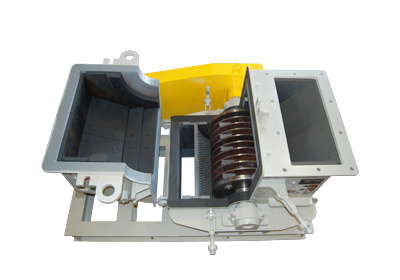

Air Swept Hammer Mill Benefits

Stedman’s full circle hammer mill boasts the features you require to deliver the finer grind you want:

- Higher throughput due to the greater screen area

- Air swept design allows the mill to operate lower temperatures, preventing stickiness or other heat problems

- Handles up to 35 tons per hour

- Compact size means small footprint

- Accessible doors

- Quick release screens

- Reversible adjustable intake

Industries

Stedman Machine Company’s line of size-reduction equipment is found in industries and applications from A-to-Z. In fact, it would be easier to list the industries that don’t employ some type of size-reduction equipment!

Rock & Aggregate Crushers

Specialty uses of limestone include the manufacturing of pharmaceuticals, toothpaste, paint, paper, caulking, and glass.

Energy & Biomass Pulverizers

One of the first uses for the cage mill was as a coal pulverizer. By 1900 Nathan Stedman had built more than 100 cage mills designed to crush coal.

Ceramic & Brick Clay Crushers

Stedman revolutionized material preparation for the brick, clay, and ceramic industries by introducing more cost-efficient processes.

Size reduction for a variety of minerals

Stedman crushers, mills, and grinders are used in nearly every mineral and mining industry. Whether you are processing coal, rock, salt, iron ore, wood chips or clay, we have your solution to size reduction.

Industrial Food Rendering Crushers

Stedman ensures nothing goes to waste by delivering reliable, durable pulverizers and crushers perfect for handling food waste and food rendering.

Agricultural Crushers

Stedman delivers high-performing pulverizers crushers perfect for agricultural uses including crushing lime, processing animal feed, and reducing grain corn.

Industrial Herb & Spice Crushing Equipment

Stedman delivers high-performing, low-maintenance pulverizers crushers ideal for large-scale grinding, milling, and processing of herbs and spices.

Grain Processing Equipment for Distilleries

Stedman delivers high-performing, low-maintenance pulverizers & crushers ideal for large-scale grinding and milling grain and corn to supply distilleries.

Fertilizer Crushing Equipment

Stedman’s reliable, durable lump breakers, chain mills, and cage mills are expertly engineered, sturdily constructed, and rigidly tested to meet the specifications you require for heavy-duty fertilizer processing and size reduction.

Test Before You Buy™

The Stedman Testing and Toll Processing Facility is the place to test your material in our full size equipment. If it can be crushed, ground, pulverized or mixed, chances are we’ve done it. We have more than 10,000 test reports to help get you to the best solution quickly. To learn more about what to expect from testing, read our article that ran in POWDER BULK ENGINEERING magazine.

Additional Information

Delivering equipment and service you deserve

For nearly two centuries, Stedman Machine Company has produced quality, reliable and durable size reduction and industrial crushing equipment. Stedman has expert field service and installation technicians ready to assist with all maintenance and equipment commissioning needs.

- Unsurpassed industry experience – operating since 1834

- State-of-the-art equipment testing facilities

- Dedicated, professional staff

- Parts and service available 24 hours a day

Stedman Machine is a leading cement crusher manufacturer with the capability to provide customer service across the globe. Our experienced team will work with you to create the best impact crusher system to make your processes the most efficient. Call us for more information!

Contact Us

Our 24 hour parts and service department along with our inventory of wear parts allow us to provide the fastest response time for parts and service.