View All Size Reduction Equipment

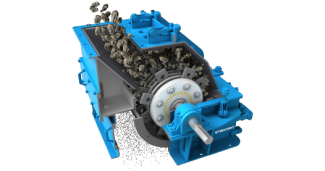

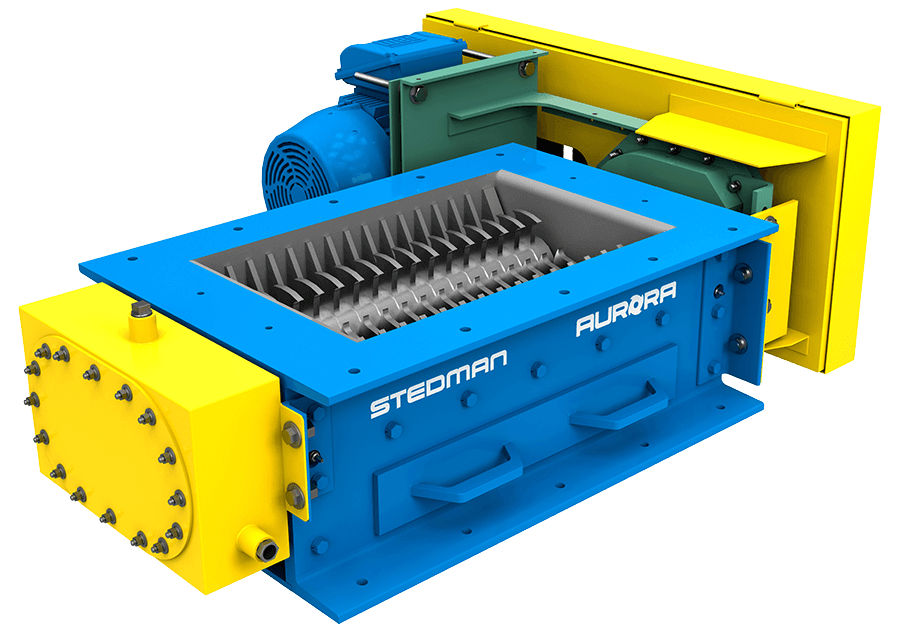

Industrial Food Waste Crushing Equipment

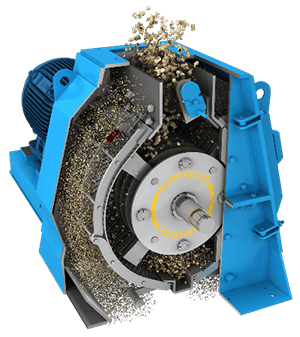

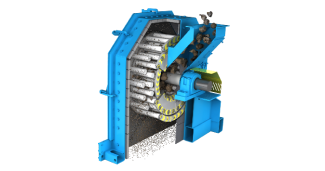

Combining decades of industry experience with hands-on expertise, Stedman’s highly-trained, professional staff can develop and deliver a customized food waste processing solution with our industrial food waste crushing equipment.

Stedman’s staff reviews your unique processing specifications, evaluates your requirements, then selects and supplies the proper industrial food rendering crushers.

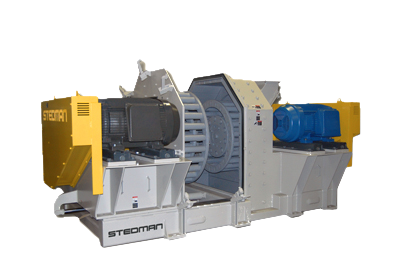

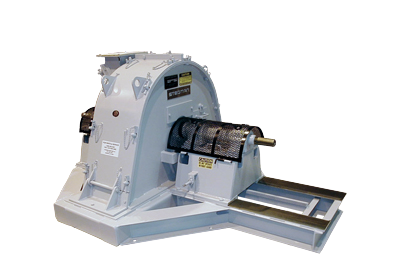

Stedman Machine’s horizontal and vertical shaft impact crushers, H-Series cage mills and full circle hammer mills provide the power and performance you need for process food waste and animal rendering.

Test Before You Buy™

The Stedman Testing and Toll Processing Facility is the place to test your material in our full size equipment. If it can be crushed, ground, pulverized or mixed, chances are we’ve done it. We have more than 10,000 test reports to help get you to the best solution quickly. To learn more about what to expect from testing, read our article that ran in POWDER BULK ENGINEERING magazine.

Additional Information

Delivering equipment and service you deserve

For nearly two centuries, Stedman Machine Company has produced quality, reliable and durable size reduction and industrial crushing equipment. Stedman has expert field service and installation technicians ready to assist with all maintenance and equipment commissioning needs.

- Unsurpassed industry experience – operating since 1834

- State-of-the-art equipment testing facilities

- Dedicated, professional staff

- Parts and service available 24 hours a day

Stedman Machine is a leading cement crusher manufacturer with the capability to provide customer service across the globe. Our experienced team will work with you to create the best impact crusher system to make your processes the most efficient. Call us for more information!

Contact Us

Our 24 hour parts and service department along with our inventory of wear parts allow us to provide the fastest response time for parts and service.