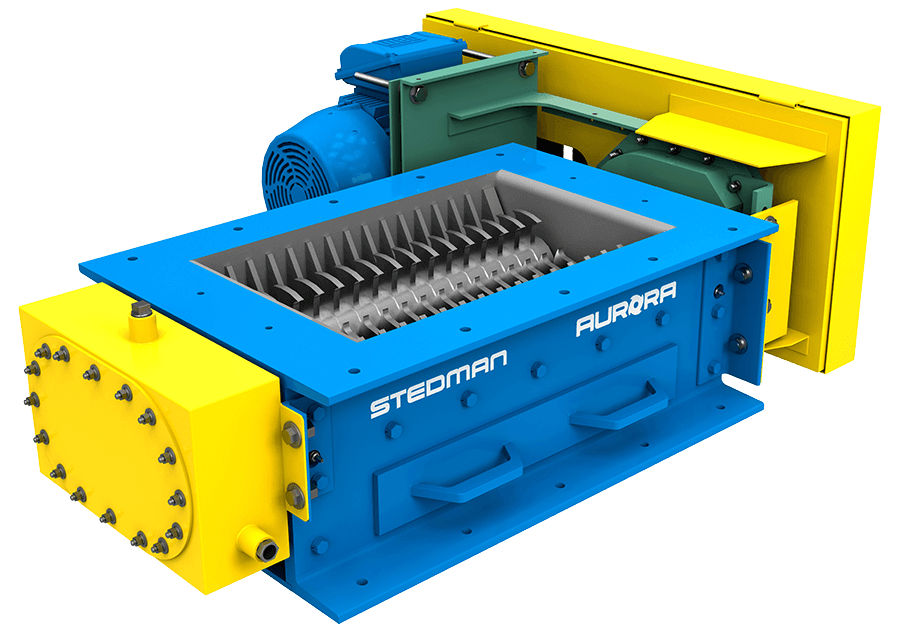

Size Reduction Equipment

Different types of particle size reduction equipment are available and each has its own method of reduction. The right size reduction machine for the task is the one that can add energy most efficiently for the application.

Test Before You Buy™

The Stedman Testing and Toll Processing Facility is the place to test your material in our full size equipment. If it can be crushed, ground, pulverized or mixed, chances are we’ve done it. We have more than 10,000 test reports to help get you to the best solution quickly. To learn more about what to expect from testing, read our article that ran in POWDER BULK ENGINEERING magazine.

Featured Products

Parts & Services

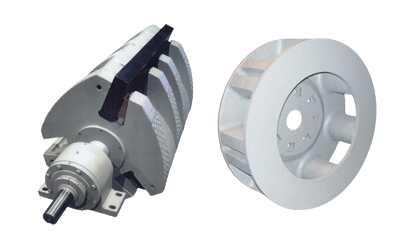

For after-sales support, Stedman has a complete inventory of impact crusher wear parts and crusher spare parts including breaker bars, wear liners, bearings, electrical components, and shafts. Cage mill parts including sleeves, bands, and disks are stocked for quick cage assembly.

- We have the crusher wear parts you need in stock to get you up and running fast – 80% of parts orders ship same day!

- We electronically track your parts order from the moment it's placed, until the minute it's shipped

- Stedman specialists work to find parts for older crushers. Some Stedman crushers are still producing after more than 50 years in service!

- We provide you with a recommended crusher spare parts list and a complete manual

Industries

Stedman Machine Company’s line of size-reduction equipment is found in industries and applications from A-to-Z. In fact, it would be easier to list the industries that don’t employ some type of size-reduction equipment!

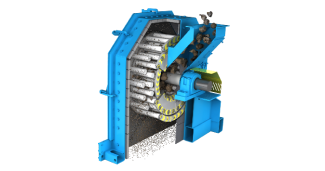

Rock & Aggregate Crushers

Rock & Aggregate Crushers are used in applications such as Limestone, Gypsum, Sandstone, and more. Our field-proven rock and aggregate crushing equipment will give you years of dependable and profitable service. Innovative features make Stedman machines superior in performance.

Let us help in choosing the right aggregate crushing equipment for your application!

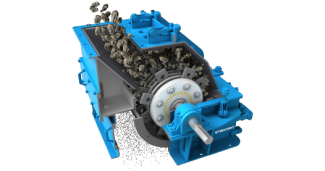

Energy & Biomass Pulverizers

One of the first uses for the cage mill was as a coal pulverizer. By 1900 Nathan Stedman had built more than 100 cage mills designed to crush coal.

Ceramic & Brick Clay Crushers

Stedman revolutionized material preparation for the brick, clay, and ceramic industries by introducing more cost-efficient processes.

Size reduction for a variety of minerals

Stedman crushers, mills, and grinders are used in nearly every mineral and mining industry. Whether you are processing coal, rock, salt, iron ore, wood chips or clay, we have your solution to size reduction.

Industrial Food Rendering Crushers

Stedman ensures nothing goes to waste by delivering reliable, durable pulverizers and crushers perfect for handling food waste and food rendering.

Agricultural Crushers

Stedman delivers high-performing pulverizers crushers perfect for agricultural uses including crushing lime, processing animal feed, and reducing grain corn.

Industrial Herb & Spice Crushing Equipment

Stedman delivers high-performing, low-maintenance pulverizers crushers ideal for large-scale grinding, milling, and processing of herbs and spices.

Grain Processing Equipment for Distilleries

Stedman delivers high-performing, low-maintenance pulverizers & crushers ideal for large-scale grinding and milling grain and corn to supply distilleries.

Fertilizer Crushing Equipment

Stedman’s reliable, durable lump breakers, chain mills, and cage mills are expertly engineered, sturdily constructed, and rigidly tested to meet the specifications you require for heavy-duty fertilizer processing and size reduction.