More About Particle Size reduction

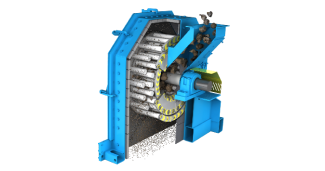

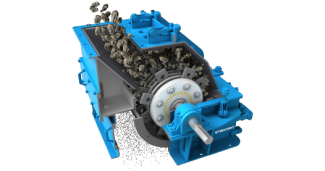

Today, there are many different size reduction machines available to make little pieces out of big ones. Particle size reduction equipment includes primary impact crushers and secondary crushers as well as milling machines - cage mills, hammer mills, pulverizers, and grinders.

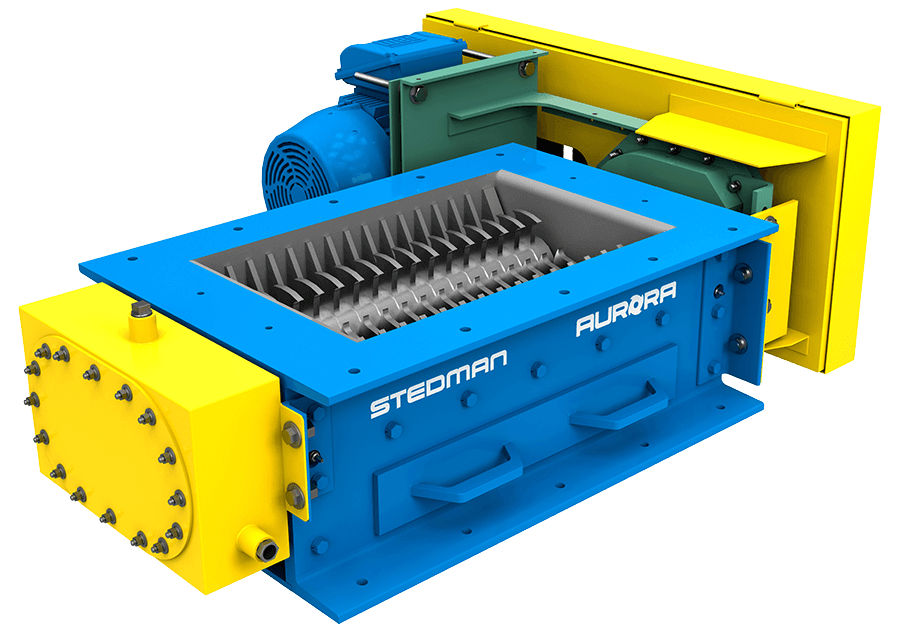

Stedman manufactures a full line of particle size reduction equipment — primary impactors, secondary crushers, tertiary impactors, plus cage mill pulverizers, hammer mill crushers and lump breakers for the aggregate, mining, and industrial markets. Materials processed fall into broad categories including abrasive, non-abrasive, wet or dry, sticky, and friable. Stedman's experience evaluating these factors helps target the correct size reduction equipment for each unique project.

Test Before You Buy™

The Stedman Testing and Toll Processing Facility is the place to test your material in our full size equipment. If it can be crushed, ground, pulverized or mixed, chances are we’ve done it. We have more than 10,000 test reports to help get you to the best solution quickly. To learn more about what to expect from testing, read our article that ran in POWDER BULK ENGINEERING magazine.

Why Stedman?

For nearly two centuries, Stedman Machine Company has produced quality, reliable, and durable size reduction and industrial crushing equipment. Stedman has expert field service and installation technicians ready to assist with all maintenance and equipment commissioning needs.

- Unsurpassed industry experience – operating since 1834

- State-of-the-art equipment testing facilities

- Dedicated, professional staff

- Parts and service are available 24 hours a day

- Installation & maintenance services

Size Reduction Machine FAQs

As you look for particle size reduction equipment, if you have the answers to the following basic questions, a good, experienced supplier can help you maneuver through designing the best equipment for your application. Begin by answering these five questions:

- What raw material will be crushed?

- What's the raw material's moisture content range?

- What's the raw material's particle size range?

- What production rate should the size reduction equipment achieve (in pounds per hour, tons per hour, or kilograms per hour)?

- What particle size range must the final product have?

For processes that require frequent changeovers, particle size reduction machines with a wide range of process control and operating flexibility are the answer. Whether the materials are friable or not will affect the type of particle size reduction equipment that’s optimal. In addition to material type, the starting and final size of the milled material drives the mill selection process. Contact the experts at Stedman Machine Company to discuss which size reduction machine is best for your application.

Contact Us

Our 24 hour parts and service department along with our inventory of wear parts allow us to provide the fastest response time for parts and service.